High Temperature Die-Cuts

High temperature die-cuts tape is a specialized adhesive tape solution that is designed to withstand extreme heat, making it ideal for use in high-temperature applications. Die-cutting is a method of cutting shapes or patterns out of the tape material with precision, ensuring that the tape fits the specific contours of a particular component.

The manufacturing process involves taking a roll of high-temperature resistant material, such as a silicone or polyimide film, applying adhesive to one side, and then die-cutting the tape into the desired shape. The die-cutting process allows for precise customization to fit a particular application, lowering waste and minimizing installation time.

One of the benefits of using high temperature die-cuts tape is its ability to maintain its adhesive properties even at elevated temperatures. Heat-resistant tapes are specifically formulated to withstand temperatures ranging from 150°C up to 260°C. This makes them ideal for use in high-temperature applications such as automotive engines, aerospace components, industrial ovens, and furnaces.

Another benefit of high temperature die-cut tape is its ability to provide excellent electrical insulation. Die-cutting ensures that the tape conforms precisely to the surface of the component, creating an effective barrier against electricity and heat. This capability makes high-temperature die-cuts tape ideal for use in electrical and electronic applications, including printed circuit board (PCB) insulation.

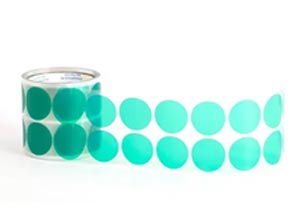

High-temperature die-cuts tape in Shri Enterprises comes in different types and sizes, depending on the specific applications they are designed for. For instance, some tapes come with a pressure-sensitive adhesive (PSA) backing, while others have a thermosetting adhesive coating that requires heat to activate.